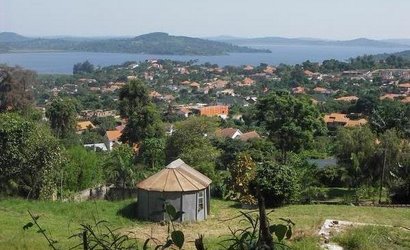

In Uganda, agriculture is everywhere. Very common crops include maize, cassava, beans, and g-nuts (or peanuts, as they are called in the United States). Groundnuts are grown mainly in the eastern and northern parts of Uganda, but are grown in small amounts all over the country.

While in Uganda, Matt Brown (Babson MBA '07), Alex Souza (Babson'09) and Ben Salinas (Olin'09) are working with U.S. based non-profit organization, Full Belly Project (www.fullbellyproject.org) and local farmers on a new venture.

Currently, half a billion people across the world receive their primary source of protein from g-nuts. In fact, over 90% of all g-nuts are grown in developing countries. In Uganda, almost all g-nuts are grown by subsidence farmers. In order to use and sell their g-nuts, women and children must shell the nuts. This is a very tedious task that is done by hand. For 2 months out of the year, women and children in Uganda will spend all day shelling g-nuts by hand. In addition to the tremendous time commitment, the tedious work is very hard on their hands.

In 2001, a man named Jock Brandis (http://en.wikipedia.org/wiki/Jock_Brandis) invented a simple machine that shells peanuts. Made out of concrete and a few metal pieces, the machine can be locally made and is a great example of "Appropriate Technology."

This sheller can shell nuts at a rate of 50 kg per hour, 50 times faster than women can do by hand. And this machine only costs about $75 to make in Uganda.

This sheller can shell nuts at a rate of 50 kg per hour, 50 times faster than women can do by hand. And this machine only costs about $75 to make in Uganda.On Wednesday and Thursday, we visited several farms in Uganda and spoke with cooperatives about growing g-nuts. The women in the co-ops were extremely excited about the opportunity of having a shelling machine that could save them hundreds of hours of work a year and offer them a chance to bring in extra income (shelled nuts demand twice the price as unshelled nuts on the market). However, this raises the question of how we can effectively distribute these machines to the farmers of Uganda. While it seems like a very little amount for most Americans, $75 represents a large portion (approximately 20%) of an Ugandan farmer's annual income, so selling the shellers directly to the farmers is not an option.

Now, let me tell you a story about the concrete industry. Worldwide, the concrete industry is responsible for 5% of all greenhouse gas emissions. Due to the Kyoto Treaty and other agreements made, concrete companies are looking for ways to reduce their carbon dioxide emissions. One company, Lafarge (www.lafarge.com) which is the world's largest building materials company, has committed to reducing their greenhouse gas emissions by 20% by the year 2010. This is through a partnership with the World Wildlife Foundation.

Hima Cement, a Ugandan cement company, is a subsidiary of Lafarge and has begun to reduce their greenhouse gas emissions through a new program. To reduce their dependence on oil, they collect waste coffee husks and burn those. This has reduced their emissions considerably and also has saved them money.

Matt, Alex, Full Belly Project, and I (Ben) are working on a new program to pitch to Hima. We plan to distribute shellers to farmers and buy waste peanut shells (which most farmers burn as waste, but not for fuel) from farmers. These shells will then be purchased by Hima who will burn them in their factory. This gives us the opportunity to create a sustainable business around distributing peanut shellers. In addition to saving time, these farmers will earn a secondary income from the sale of their shells. They have told us that with this extra time and money, they will be able to grow more g-nuts to better provide for their families.

The three of us are spending our time researching how this program might take place. We have met with several businessmen and many farmers. One of the highlights of our trip has been our meeting with Dr. Specioza (http://en.wikipedia.org/wiki/Specioza_Kazibwe), the former vice president of Uganda (also, the first female Vice President in Africa). She offered valuable insight on our plan.

This next week we will spend more time talking with farmers and have scheduled a meeting with Hima for Monday. At a later date, I will share with you some of our results from our meetings.

I know I speak for all three of us when I say that this trip has been a wonderful experience.

-Ben Salinas

2 comments:

Wow! Not only does this seem like an innovative business opportunity, using waste as an actual product to generate revenue for investment, but the opportunity to meet the former VP of Uganda is amazing. I am happy to hear that everyone is finding the experience rewarding.

Michael

Good going. Glad to see it's exciting and productive both for the students and the local people.

One thing though--if you "search" the Babson site for "Uganda" or "Uganda trip" you don't get anything after 2005!

Hope that someone get's these posts to the Babson PR office--I'm sure January 15th (MLK Day) will be a specially remembered Day of Service for all on the class trip.

Good luck!

Post a Comment